Research and development in order to provide the very best marine apparel, is a key process in the way our Gill design team function. With over 45 years of expertise, they always start with one question – “what is the need of the consumer?”.

This year saw the launch of our new Offshore Boots, which have already made their maiden voyage around the world in the Vendée Globe 2020 -2021, worn by skipper Louis Burton who came third overall in the world-renowned race.

Louis Burton training for the Vendée Globe 2020-2021, wearing the Gill OS1 System (available to purchase in September 2021) and the Offshore Boots.

Now, available to purchase on our website here, these boots have a rich history of over four years of research and development processes in order to make them into the very best that they can be for our wearers.

The process

The initial idea of our Offshore Boots can be traced back to the 2016-2017 Vendée Globe, when our design team were working with New Zealand yachtsman Conrad Coleman. In combining his clear thoughts on what he needed for the race with the expertise and knowledge of our design team, the starting brief was to create a lightweight, flexible, completely waterproof boot that would integrate into Conrad’s salopettes in order to provide that extra barrier of protection against the elements.

Another key focus for our team was to create a sole whereby he could ‘feel’ the deck. If Conrad stepped on a rigging line, the boots should be able to fold over and grip to the deck.

“The initial idea behind the new Offshore Boot dates back to the 2016-17 Vendée Globe. We had been working with Conrad Colman who had really clear thoughts as to what he wanted as a competitive offshore sailor. The starting brief was a lightweight, flexible boot that was absolutely waterproof, and would remain waterproof over 1000’s of nautical miles. In addition, he wanted a way of integrating the boot with his Salopettes so they provided an extra level of protection against seawater flushing over the deck and around the cockpit. He also wanted to ‘feel’ the deck, so the outsole needed to flex and retain direct contact with as much of the deck surface as possible. If he stepped on a rigging line, he wanted the boot to almost fold over it and grip the deck instead of rolling on the rope and losing his footing.”

Matt Clark, Gill Product Development Director, February 2021.

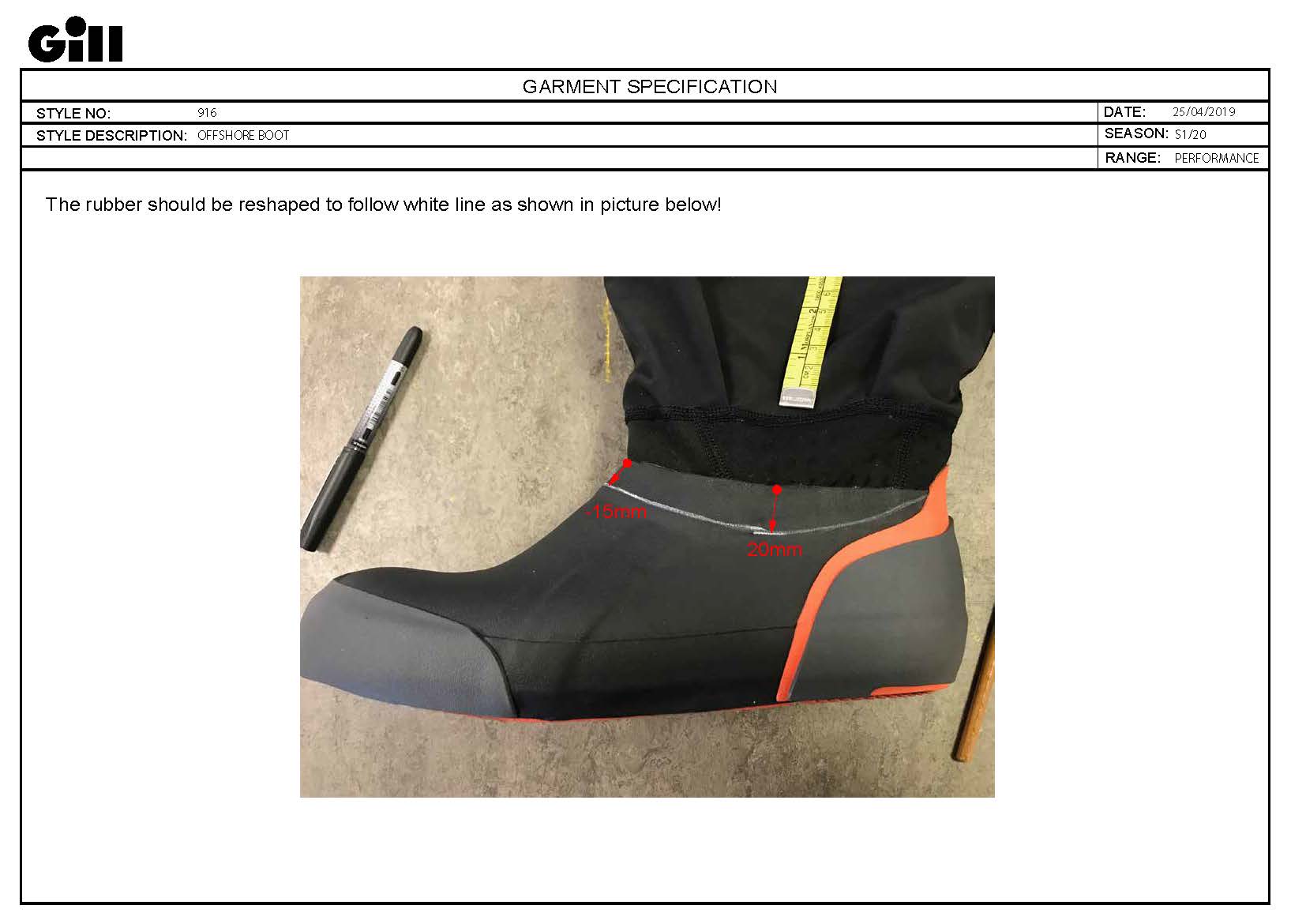

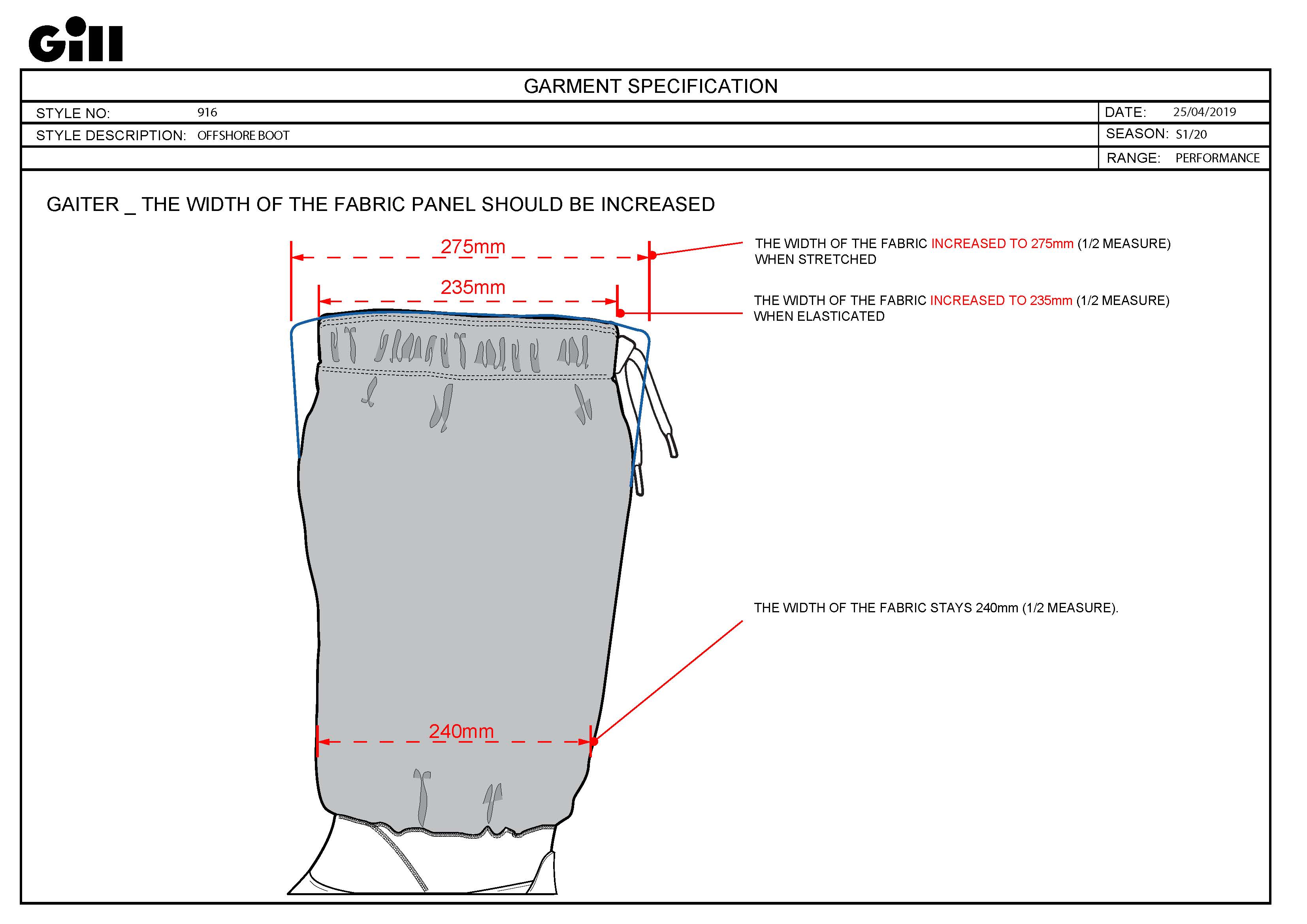

The Offshore Boot garment specification drawings as used by our factories.

The Offshore Boot in early prototyping stages.

The Gill team got to work, with early prototyping involving hot-gluing fabric gaiters to boots in order to test them in their offshore environment out at sea. This hands-on approach meant they could gather first hand feedback and observation that they just wouldn’t get from lab experiments.

Using this research, the team came up with the internal 3mm thermal neoprene structure, meaning that the wearer can comfortably tuck them inside their salopettes. Combined with an external gaiter, developed with our best XPLORE+ 3-layer fabric to offer the most effective waterproofness and protection, the boots would securely fasten over the wearers salopettes to offer the complete top to toe waterproof solution when worn with our other sailing systems.

To meet the requirements for Conrad to ‘feel the deck’ through his feet when onboard, our team created a barefoot style inner sole and flexible outsole with non-slip razor cut ridges for a safe grip and to ensure as much contact with the deck surface as possible.

This, combined with the reinforced heel, instep and toe, meant the boots wouldn’t roll on objects and cause him to lose his footing.

Following these tests were four years of constant experimenting, developing numerous samples as well as perfecting and tweaking the best fabrics, resulting in the boots you can purchase today.

Louis Burton and the Vendée Globe 2020-2021

When French skipper Louis Burton began testing our gear during training for the Vendée Globe 2020-2021, his first reaction to the boots was overwhelmingly positive in that he found they were incredibly comfortable, “just like wearing slippers!”. In January 2021, when Louis safely arrived back in Les Sables-d’Olonne after 80 days of freezing cold temperatures, giant waves and fierce winds, this only verified the performance capabilities of these boots, a true testament to how they stand up to the water, wind and wear.

“His first reaction was overwhelmingly positive – the comfort is incredible, it’s just like wearing slippers!”

Matt Clark, Gill Product Development Director, February 2021.

Since the end of the race, Louis’ debrief notes and product feedback from over 80 days of constant use will now feed into the next generation of this style, so keep an eye for future developments!

Photo credit: Simone Staff

Photo credit: Simone Staff

A sailor wearing the Offshore Boots while out at sea.

So why do we think Gill products are set apart from our competitors?

One of the founding principles that Gill started with was the need to continuously develop better products through constant innovation, and this is still true today. There is a nonstop flow of fabrics and components through our lab facility and independent partner labs, all which ensure that not only are our products fit for purpose, but that in repeat production, we continue to meet the same high quality and performance standards.

“We also mirror this attention to detail at our production facilities, with some styles such as the OS2 Offshore taking 2 hours to test and guarantee as being 100% waterproof. Behind all of this is an affinity with the consumer and an understanding of their needs – constant product feedback, athlete input and our own on the water adventures all help drive the design process.”

Matt Clark, Gill Product Development Director, February 2021.

The testing process as described above is reflected for every single Gill product, an example of which is our bestselling OS2 Offshore system which takes over 2 hours to test in order to guarantee that it is 100% waterproof.

In every design development, choice or improvement made, we pride ourselves on our affinity with our consumer, athlete feedback and understanding of their needs, all combined with our own outdoor experiences which forms the core motivation for driving product development.

Interested in how we select and test our fabrics? Read our blog to find out more about how we go right down to every microbe of the products we sell in order to create products best suited to a marine environment.