At Gill we understand that time on the water is more than just braving the elements – it’s about thriving in them, which means sailing kit needs to be reliable and more importantly comfortable. This belief drives us to take a unique approach, creating proprietary fabrics for our waterproof apparel that redefine the industry standards of excellence. Our commitment goes beyond industry norms; we subject our waterproof products and proprietary fabrics to rigorous testing, ensuring that when you need to stay protected, you can trust Gill—no compromise. We understand that true comfort is not just about staying dry; it’s about feeling secure and confident in every moment on the water.

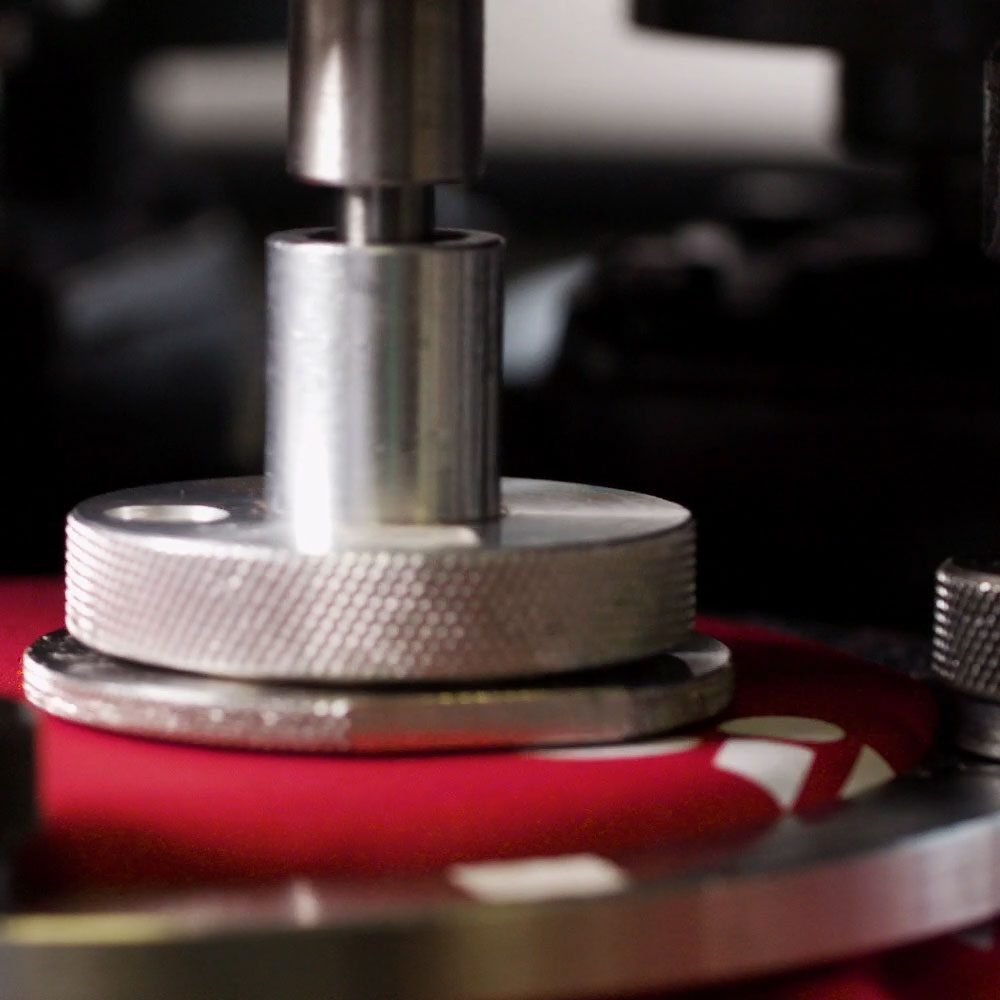

Hydrostatic Head Testing: Defying Water Penetration

Our commitment to excellence begins with Hydrostatic Head testing, a meticulous examination of how waterproof our fabrics are. This measurement, expressed in mm, represents how high a column of water would need to be before it penetrates fabric causing it to fail. At Gill, we believe in setting the bar higher when it comes to waterproof performance. While some international standards permit up to three water droplets to permeate before declaring a fabric non waterproof, at Gill we take a different approach – we stop at the first droplet. Our minimum testing threshold is 10,000mm, although the majority of our fabrics continue to perform well over an impressive 20,000mm, with our OS1 Ocean XPLORE+ fabric still waterproof over 30,000mm. Rest assured, our products are engineered to defy water penetration and provide unparalleled protection in the harshest conditions.

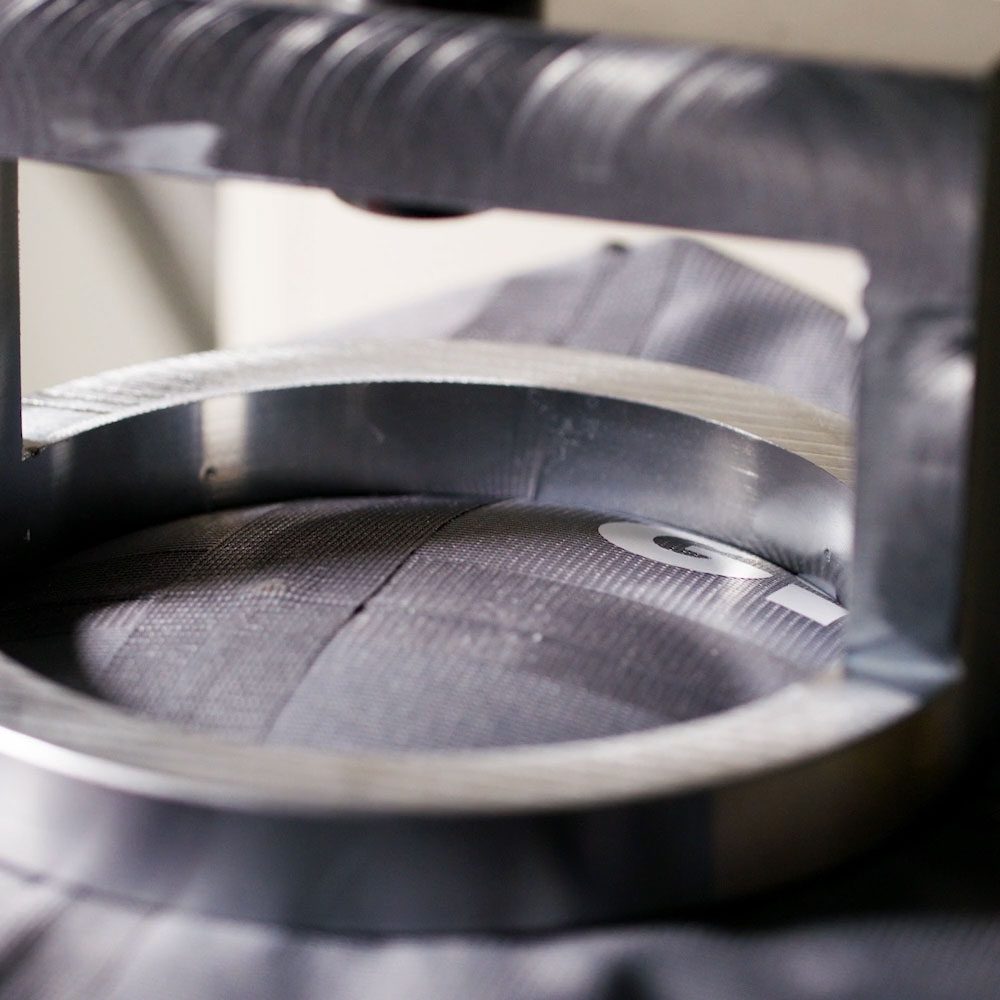

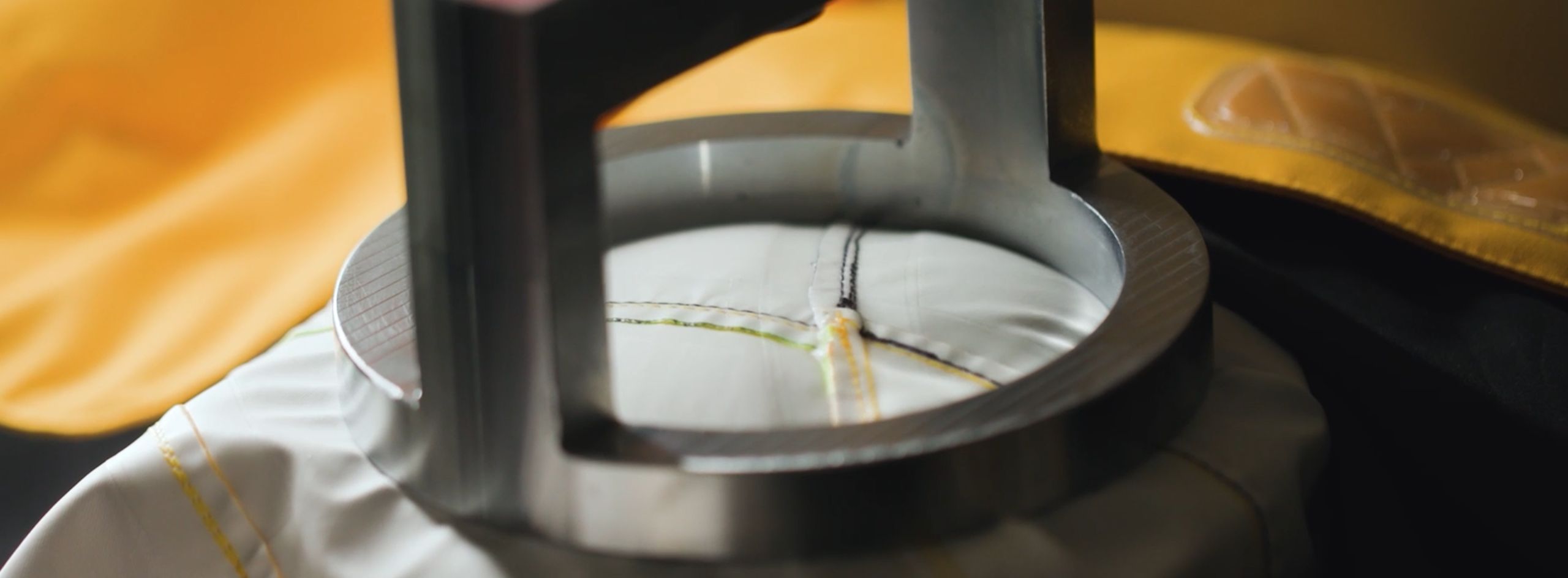

Martindale Testing: Unmatched Fabric Durability

To assess the durability of our fabrics, we employ the internationally recognised Martindale Test, also known as the ‘Rub Test’. Our version of this test yields true-to-life results by subjecting the fabric to continuous abrasion rather merely rubbing two cloth swatches together. Using a Martindale machine, a piece of fabric is placed between two discs, with one disc oscillating grit paper across the fabric until signs of distress appear. We hold our waterproof products to a minimum testing standard of 10,000 oscillations, which is three continuous hours of rigorous grit paper testing. Notably, our OS1 jacket undergoes an extensive 8-hour Martindale test, and where reinforcement fabrics are used such as the seat of the jacket or seat and knee area of the salopettes it is an impressive 33 hours of continuous abrasion testing ensuring unmatched durability for your adventures.

Beyond the Norm: Our Commitment to Quality

At Gill, we don’t just meet industry standards; we redefine them. Our dedication to pushing the boundaries of testing ensures that our waterproof products not only meet your expectations but exceed them. But we don’t stop there, in conjunction with our stringent lab tests we recognise the importance of real-world testing, where the elements are unpredictable, and conditions are challenging. Sailors wearing our apparel become ambassadors of durability as they brave the roughest oceans, providing invaluable insights into the performance of our gear in the harshest environments.